Electrolux: Heading towards a climate neutral company

Desde la planta de Rosario, Mariano Noguerón, Director de Manufactura, comparte el éxito alcanzado por el programa "Basura Cero", mediante el cual se trabaja a diario para enviar menos del 1% de los residuos generados al relleno sanitario, logrando un 95% entre reciclaje y reutilización.

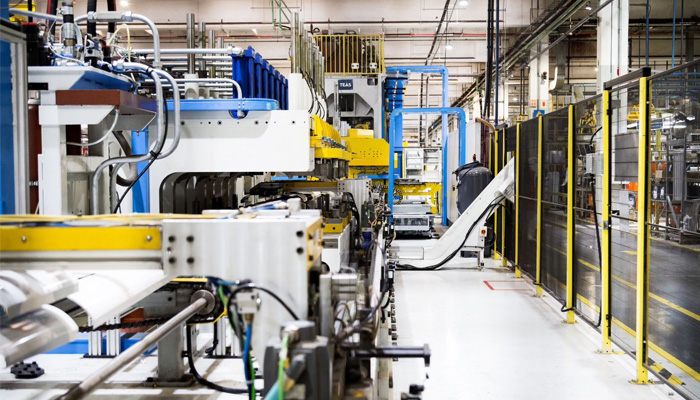

With a focus on better operations and solutions, the appliance company leads the way towards sustainability, and is challenged to integrate the entire supply chain in creating a better future. From the Rosario plant, Mariano Noguerón, Manufacturing Director of Electrolux Group, shares the success achieved by the “Zero Waste” program, through which we work daily to send less than 1% of the waste generated to the landfill, achieving 95% between recycling and reuse.

By Claudia Carrivale

prensa@editoracycargentina.com.ar

Currently, environmental sustainability is a global need that requires a comprehensive approach. What are the specific areas where Electrolux carries out its management?

Sustainability is something we all need to do to take care of the planet, and consumers are demanding it. Electrolux has that focus in the veins, we have been working on it for a long time. As in any large company, there are objectives that are implemented gradually, and Our ten-year goal is to be “Climate neutral and 100% sustainable.”

Clearly today we recognize the significant value that shareholders assign to sustainability. Starting from that perspective, we execute policies that promote it, understanding that it goes beyond short-term financial results. In sustainability, it is often known that one invests without obtaining immediate benefits, but with the certainty that they will be obtained in the future. At Electrolux there is investment and an ambition for sustainability throughout the supply chain.

We base our management on three pillars: “Better Company” focused on our internal operations, “Better Solutions” focused on the development of more environmentally friendly products, and “Better Living” to raise customer awareness about the sustainable use of products..

How is this strategy implemented at the local level?

We focus on applying the 3R practices to care for the environment: Reduce, Reuse and Recycle. For several years we have been implementing concrete actions in the operations of our plants to guarantee a positive impact.

In the Latin American region, we have five plants, and our local headquarters has operated for more than 25 years in Rosario; being one of the largest in the industrial park and employing more than 700 people. Here we focus on a solid policy of waste reduction, energy efficiency and responsible use of water.

We carry out the Zero Waste Program (Zero Waste to Landfill), certified globally by Intertek. The goal of the program is to achieve “zero waste to the landfill,” which implies that no more than 1% of the waste generated can be destined for these landfills. A great fact is that all the plants in Latin America have obtained this certification, and in Rosario we achieved it two years ago.

Has the Rosario plant achieved less than the 1% volume required to achieve certification?

Yeah, we are averaging 0.8%. It is a monitoring that is done monthly through specific indicators. We invest in meters that allow us to control the source of each type of waste. It is a very operational job, and as plant director I individually follow those indicators.

In addition to the 1% requirement, another rule of the program allows us to allocate up to 3% of total waste for energy purposes (co-processing), that is, waste that is burned to generate energy.

So if we have less than 1% destined for landfill, and no more than 3% of everything we generate that has to go to energy, it is guaranteed that 96% has to be recycled, and that is our reality and our operational strength, we have a device that recycles 96% of everything we generate.

Before reaching the “recycle” phase, we implement internal programs focused on reducing. Some require more investment and others are training on behaviors and habits in the plant.

Regarding the recycling stage, the most important thing is to segregate, from the waste generated individually, for example in the plant canteen, to the materials discarded in manufacturing. After separation, we classify the different materials, such as cardboard, metal, plastic, etc., and this allows us to select and decide what to recycle and for what purpose, all with the goal of maximizing reuse.

What is the investment plan that you have been implementing to carry out the reduction of CO2 emissions?

One of the points is to invest in more energy efficient equipment and switch to less polluting technologies to drive clean operations.

Reducing CO2 emissions is the mother of all our sustainable goals. We propose a reduction in plant and offices, with certification as the next step. For the Rosario plant, achieving climate neutrality in operations would be a significant achievement, especially in an industry of this type.

We have successfully established the “Zero Waste” program and are committed to maintaining it. And for the rest of the programs and actions, the fundamental premise is that any new element acquired for use in the factory does not generate emissions. We have a benchmark worldwide that, if we say that we are going to go out and buy equipment, it has to be lower consumption and more environmentally friendly.

Last year we made significant investments, such as the acquisition of compressors for plant air. We also changed all the forklifts from gas to electric, and we are close to changing the kitchen in the dining room. In 2019 we incorporated a state-of-the-art packaging system (Stretch Hood) for white goods and refrigeration, an Italian machine that stretches the bag instead of heating it to shrink it. That is an investment in sustainability because it had no other purpose, we had an oven that worked, the product was good and it was good for the customer. However, with this investment, natural gas is no longer consumed in this process.

And what is the approach for the rest of the supply chain?

Leaving the plant is also a job to do. Electrolux's ambition is to extend its approach to a more circular economy to the entire chain, from transportation and logistics to more sustainable materials and business models. We also prioritize the development of products that are more efficient in the use of resources and invite users to adopt more environmentally friendly use practices.

At a global level, we are already implementing sustainable experiences in logistics, such as in Sweden, where frequent deliveries with electric trucks are being tested.

In relation to the products themselves, we can have a perfect plant and impeccable logistics, but if what I distribute is not thought of as an improvement it will not have much impact on the planet. Therefore, we focus on improving the manufacturing and design of our products using more recyclable materials, without compromising quality or performance. And we also continually work on improving the energy efficiency of these appliances.

That is the north of Electrolux, our spirit: work throughout the chain and take the possible steps towards sustainability, recognizing that it takes investment, time and effort.

CERTIFICATIONS

The certification granted by Intertek for the “Zero Waste” program is added to other recognitions obtained by the Rosario plant, such as the ISO 50,001 and 14,001 certification, which guarantees that Electrolux is a sustainable and environmentally friendly company, and the Platinum Certification of the internal Green Spirit program, one of Electrolux's Sustainability programs to reduce emissions, promote the rational use of water, reduce energy consumption and migrate towards energy. clean.

Latest news

Outstanding sector